Washing Ranges

SWASTIK offers a wide range of Open-Width and Combined Open-Width and Rope-Washing Ranges for Cotton, Synthetic and Blended Fabrics for Washing-of desized fabrics, Scoured and/or Bleached or Mercerised fabrics, Dyed Fabrics and for Developing dyed fabrics as well as After-Print Washing. Swastik also offers Relax Scouring and Washing machine for Viscose-Polyester and Polyester Fabrics.

The Washing Range can be built using a combination of washing compartments.

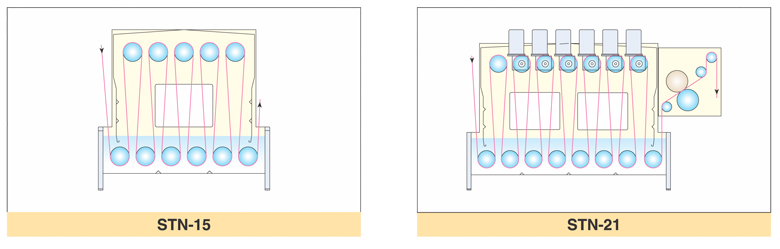

Closed Single Loop Washer Stn-15, Stn-18, Stn-21

Closed Single Loop Washer Stn-15, Stn-18, Stn-21

| – Closed Single Loop Washer STN-15, STN-18, STN-21. |

| – Closed Single Loop Washer with Stripper Roll STN-18, STN-22. |

| – Closed Double Loop Counter Threaded Washer STN-20, STN-25, STN-30. |

| – Closed Double Loop Counter Threaded Washer with / without pressure roller STN-20CP, STN-25CP, STN-30CP. |

| – Super Jet Washer T-850. |

| – Twin Reel Super Jet WasherT-1050. |

| – Conveyor (Dwell Zone) Washer CW100 & CW150. |

| – Open Width Closed Relaxing Tank. |

| – Hydro Jet Washer HJ-20 and HJW-20. |

| – Open Washers -ST-12, ST-15, ST-20. |

| – Rope Washer-Niagara. |

Closed Single Loop Washer Stn Series

Closed Single Loop Washer Stn Series

This Open-Width Washing Compartment consists of a Stainless Steel Trough with low liquor contents. Partition can be provided to obtain effective Counter Current flow of Water and Fabrics. The washed fabric comes in contact with fresh water which improves washing efficiency. There is high liquor turbulence with quick liquor exchange resulting in effective removal of dissolved Chemicals and Impurities.

Top Rollers are fixed in bearings. Bottom rollers are fixed in bearings mounted outside the tank with mechanical seals or fixed in self lubricated bushes. All compartments are equipped with direct or indirect heating arrangement as required.

The washing compartments are equipped with medium pressure squeeze nips for intermediate compartment and heavy squeeze nip for high extraction at the delivery end. Rubber Rollers are made from special rubber compounds suitable to resist the chemicals or dyes used as required by process.

Impregnator

Impregnator

SWASTIK Impregnators are designed for M.A.T. and equipped with Wiper Rollers of suitable rubber to obtain 100% or more pick-up (up to 130% )

A vacuum slot is located at the entry of fabrics in impregnator from preceding Hi- squeeze Nip for certain qualities of fabrics.

Fabric from Vacuum Slot / Hi-squeeze Nip passes through the trough with minimum liquor for light interchange dip before being subjected to a spray of chemicals with designed concentration and quantity with the help of a well designed, fully automatic dosing system.

A set of wiper Rollers are provided to enable uniform add on, as may be required.

Closed Double Loop Counter-Current Washer Series Stn

Closed Double Loop Counter-Current Washer Series Stn

This is a highly efficient Open-Width Washer with double loop threading of fabrics where two adjacent fabrics strands move in opposite directions, creating great turbulence which ensures very high washing efficiency.

The Trough can be provided with partitions to obtain Counter-Flow, wherein cleaner / washed fabric comes in contact with cleaner water as the fabric advances.

These compartments have all top rollers fixed in bearings, and on request, can be provided with Torque motors on individual or alternative rollers.

Bottom rollers are fixed in bearings mounted outside the tank with mechanical seals or fixed in self lubricated bushes. All compartments are equipped with direct or indirect heating arrangement as required.

Closed Double Loop Counter-Current Washer Stn-Cp Series

Closed Double Loop Counter-Current Washer Stn-Cp Series

STN-CP is a wash tank where the fabrics passes two adjacent strands in opposite directions and gets squeezed just before leaving the last roller of the set. This movement of fabric in opposite directions creates high turbulence which, with the dip Squeeze arrangement, results in better washing results. Top Squeeze Rollers are covered with rubber to withstand temperature up to 95�C – 98�C. Top rollers are fixed in bearings and provided with Torque motors on individual or alternative rollers.

Super Jet Washer - T-850

Super Jet Washer - T-850

Fabricated from Stainless Steel and equipped with two high pressure pumps, Filter and re-circulation system.

The Super Jet Washer is ideal for removing unfixed colours and superfluous material from printed goods without dipping in to liquor. Both sides of the fabric are subjected to high pressure Fan Jets. Fabric is carried on a large diameter Stainless Steel reel running on bearings. The reel is fully synchronised with the following squeezer.

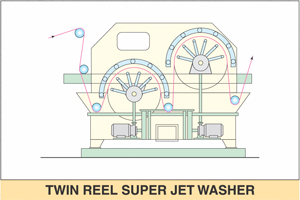

Twin Reel Super Jetwashert-1050

Twin Reel Super Jetwashert-1050

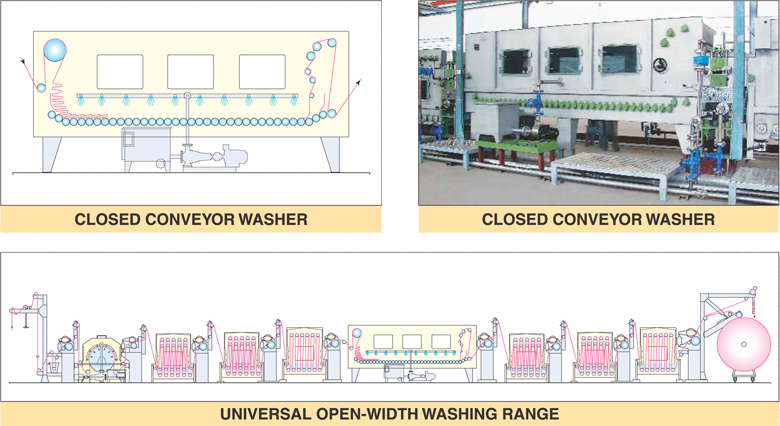

Conveyor Washer - Cw

Conveyor Washer - Cw

The fabric travels in small loops from one end to the other of the Roller Bed Conveyor and is subjected to a series of jet sprays. The unit is equipped with a high pressure pump with filter and is synchronised with the following squeezer. Conveyor Washer is ideal for loosening printing gums and thickening agents and their removal with final spray before squeezing or for relaxing the fabric. It is provided with centering and opening device before the outlet.

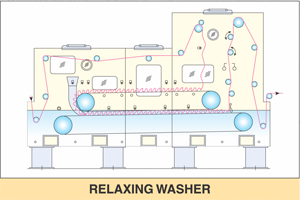

Open-Width Closed Relaxingtank

Open-Width Closed Relaxingtank

Open-Width Closed Relax Washer is used for effective scouring process on two tiers of Stainless Steel wire mesh conveyors.

Suitable for all types of woven and knitted fabrics of 100% polyester; polyester blends; texturised PV suitings and dress material.

Fabric is piled on the top of the conveyor; with direct steam jet spray and pressurised hot water jet spray alternately which breaks the hardness of closely woven fabrics.

Open-Width Closed Relax Washer is used for effective scouring process on two tiers of Stainless Steel wire mesh conveyors.

Suitable for all types of woven and knitted fabrics of 100% polyester; polyester blends; texturised PV suitings and dress material.

Fabric is piled on the top of the conveyor; with direct steam jet spray and pressurised hot water jet spray alternately which breaks the hardness of closely woven fabrics.

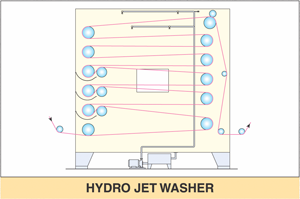

Hydro Jetwasher - HJ

Hydro Jetwasher - HJ

This is a completeiy closed Washer with a very efficient fan Jet Spray Washing System. Water is sprayed on the uppermost passage and Water trickles down, getting squeezed between the fabric and roller surface. The squeezed liquor further trickles down on to the lower passage. Thus it is perfect Counter Current Washing, ideally suited for removing impurities and dissolved ingredients from fabric with minimum water consumption. Ideal for bleached or mercerised fabrics.

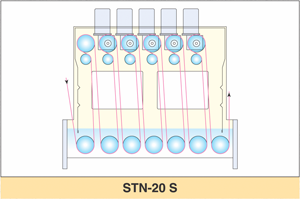

STN-20S

STN-20S

Swastik Wash Tank STN-20 S, with Stripper Rollers, has Top Roll Drive with torque motors on alternate or all guide rollers except the first, for crease-free and tensionless drive system.

This tank is characterised by low water & steam consumption, with a high washing effect. It is recommended for delicate and for pile fabric.

Woven Fabric Machinery

Terry Towel Machinery

Woven Fabric Machinery

Terry Towel Machinery

© copyright 2008. All rights reserved SWASTIK India