Compactors

Open Width Compactor – OC 400 is suitable for open width knit fabrics to achieve exact dimensional stability and a soft feel. The machine generally consists of a feeding frame with centering device and driven scroll rollers, an equalizing stenter frame with overfeed roller and brush pinning arrangement.

The entry section of Pin Frame is provided with edge spreaders IR In-Feed device, an S.S. fabricated steaming unit for uniform moistening of the fabric. The Steaming Device has stainless steel sliding shutters that allow steam to flow only as per the width of the fabric.

A low contact Glueing and Drying unit is provided with a stainless steel trough. Four selvedge drying units with infra-Red emitters are placed on either side of the machine. The delivery side section consists of edge dryer, Selvedge trimmer and a suction device, Exit roller, Width Adjustment device and the drive to the chain are housed in a exit box.

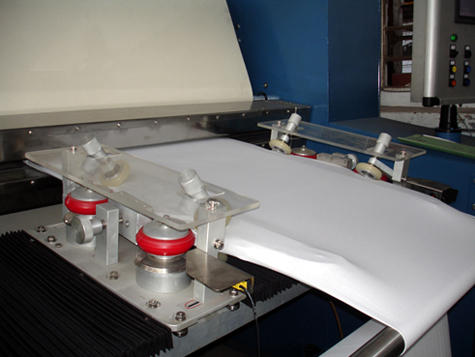

The compacting unit consists of 2 felt compacting units, each of them consisting of a Nomex felt approx. 20 mm thick, a steam heated chrome-plated center roller of dia. 400 mm, a rubber covered roller driven by variable frequency drive, a compacting pressure roller, a felt tensioning roller and a felt centering roller. Each unit is provided with a special anti-fiction sheet type shoe controlled by an electrical actuator to control the compressive shrinkage. A fabric cooling roller is provided after second felt to cool the fabric by means of chilled water circulation. Fabric Tension through the machine is controlled with the help of sensitive load cells and variable frequency drive with PLC and touch screen.

Compactor For Tubular Fabrics Model Tc-400

Compactor For Tubular Fabrics Model Tc-400

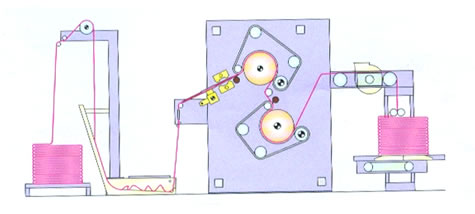

The treatment of knit fabrics in tubular form on the SWASTIK TUBULAR COMPACTOR meets the exacting standards set by customers so that garment stitched from the fabric finished on this machine will yield the lowest residual shrinkage values.

| 1. | Width control through a stepless adjustable special tubular fabric spreader driven by variable speed motor for distortion-free fabric guidance. |

| 2. | Steamping with a condensate-free steam box which is easily operated and completely made from stainless stell. |

| 3. | Compacting through two Nomex felt belts. |

| 4. | Calendaring while passing between the felt belt and the heated shrinking rollers. |

| 5. | Precision plaiting with automatic platform level adjustment controlled by folded fabric height. Alternatively, a fabric rolling system can be provided. |

The fabric is fed through the guiding system and stretcher which then takes the fabric through the steam box onto the felt of the twin compacting units. At the fabric delivery, the machine is equipped with a precision plaiting device with its platform. The height of the platform is controlled automatically and is adjustable according to the plaited fabric height.